How a Leading Manufacturer Achieved Zero Landfill for PPE Waste

- Industry

- Industrial Manufacturing

- Location

- United States

- Goals

- To help the manufacturer reduce landfill waste by implementing a sustainable PPE recovery program that transforms used materials into Alternative Engineered Fuels.

- Type

- B2B

Products used

-

Sustainability Solutions

Enabling businesses to handle waste responsibly using advanced tools and professional guidance.

The Challenge

A leading industrial manufacturer faced growing challenges around the disposal of single-use Personal Protective Equipment (PPE). With large volumes of used gloves, masks, and garments being discarded daily, the company needed a more sustainable, compliant, and cost-effective solution. Their goals included reducing landfill waste, meeting ESG objectives, and streamlining compliance with environmental regulations.

Wastebits Provides the Solution

Customized PPE Recovery Program

Wastebits developed a tailored PPE Recovery Program to meet the manufacturer’s unique operational needs. This included on-site collection bins for used PPE, managed logistics for transport, and a solution that converted difficult-to-recycle materials into Alternative Engineered Fuels (AEFs)—a cleaner, low-ash fuel source used by approved facilities. The result was a sustainable disposal method that aligned with both regulatory and ESG goals.

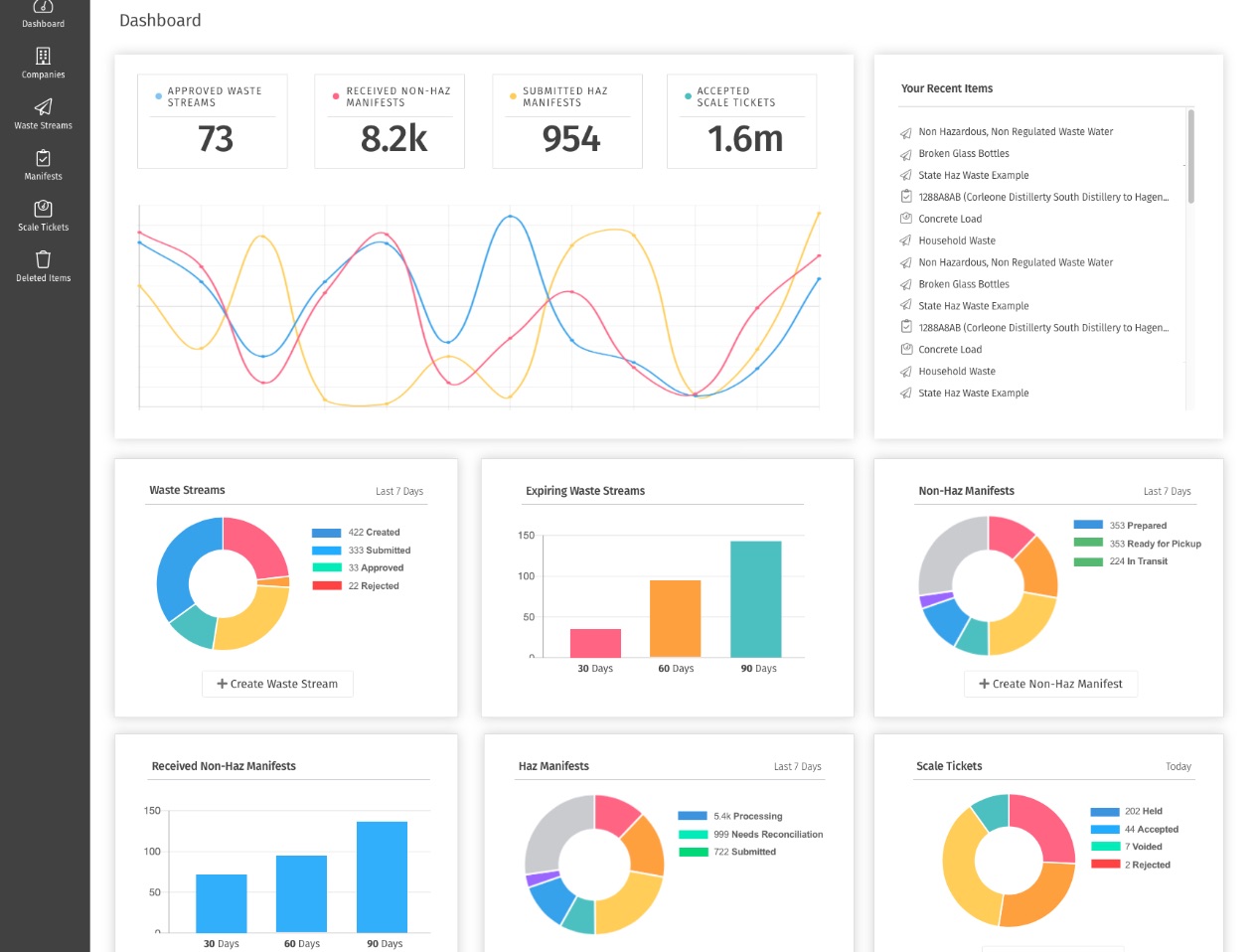

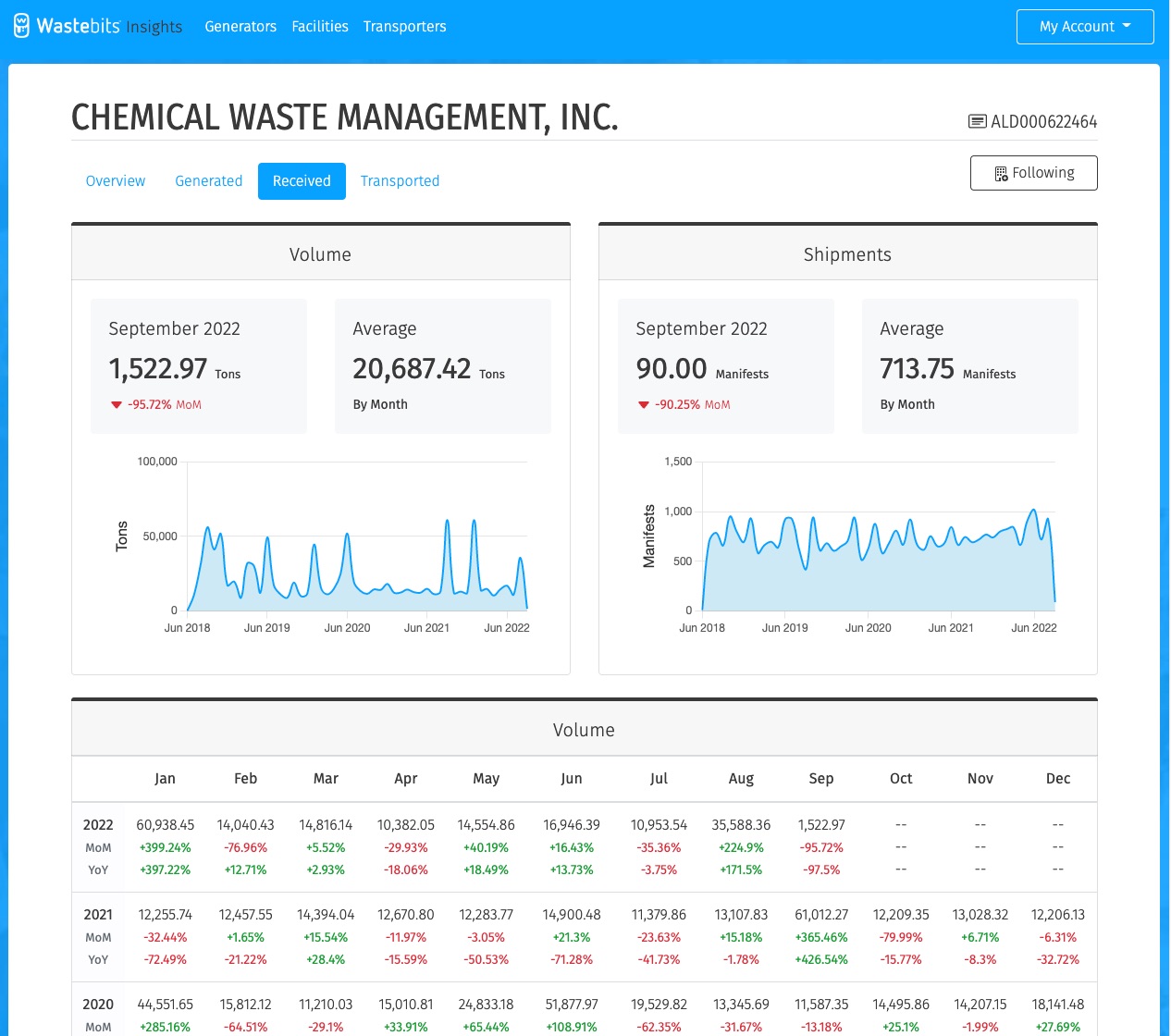

Digital Tracking and Reporting

Wastebits’ digital platform gave the facility full transparency into its waste streams. From tracking PPE volumes to generating manifest reports and audit-ready documentation, the software offered real-time insight that simplified compliance and supported ESG reporting efforts.

Training and Employee Engagement

Wastebits partnered with the facility’s environmental and safety teams to educate employees on proper PPE disposal practices. This initiative created better workplace habits and reinforced the company’s sustainability culture from the ground up.

Meaningful Results

The partnership produced measurable impact, including a significant reduction in PPE sent to landfills and a clear advancement of the company’s ESG goals. By converting PPE into Alternative Engineered Fuels, the program not only reduced the environmental footprint but also helped the company lead by example in its industry.

100%

PPE waste diverted from landfills

90%+

Reduction in environmental impact compared to landfill disposal of single-use PPE

Zero

Hazardous residues or landfill ash generated through AEF conversion

More Case Studies

👋 Let's Chat

Schedule a demo today to see for yourself how Wastebits can help run your business smoothly and increase profits.

P.S. Have you met David? He's a nice human, like you! Click the button above to see his calendar and click your preferred time (plus you'll see a picture of his sweet beard).

He'll ask a few questions and show you exactly what applies to your situation. There's no pressure, you'll make a more informed decision, and takes only 15-minutes. 🙌