Smart Waste Strategy Saves $700K+ for Leading Manufacturer

- Industry

- Manufacturing – Industrial Equipment

- Location

- United States

- Goals

- To help a leading industrial manufacturer reduce landfill waste, improve compliance, and streamline operations through smart, tech-enabled waste management.

- Type

- B2B

Products used

-

Sustainability Solutions

Enabling businesses to handle waste responsibly using advanced tools and professional guidance.

-

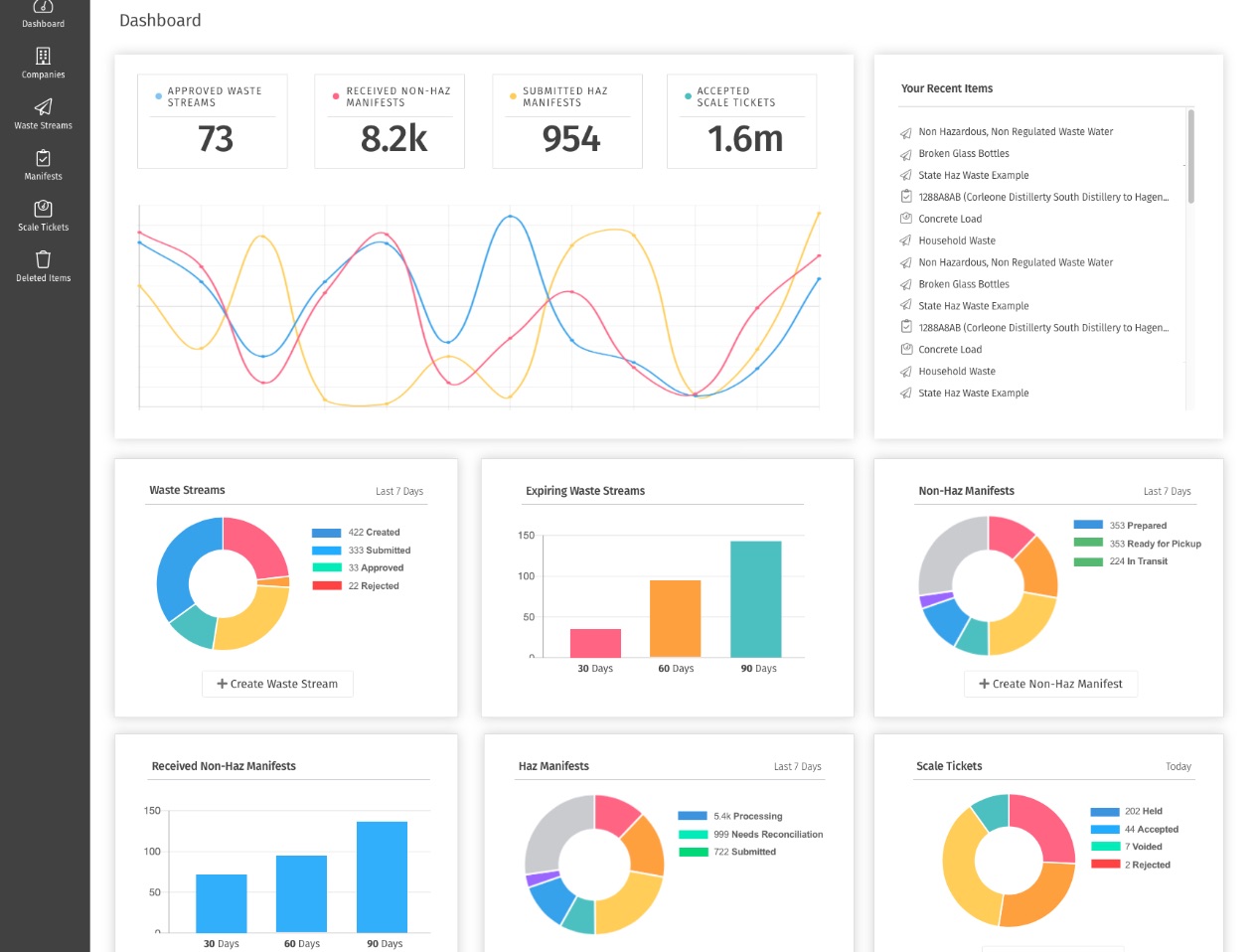

Waste Stream Management

The Wastebits software backbone to profile, manage, track, communicate and report on waste stream data.

The Challenge

A leading manufacturer of industrial equipment was facing mounting operational and regulatory pressures. With over 500,000 pounds of reusable material being sent to landfills each year, rising risks of RCRA non-compliance, and downtime from reactive maintenance practices, the company needed a more strategic and sustainable approach to waste management. Fragmented systems, vendor turnover, and an aging wastewater treatment process further complicated their operations—requiring a trusted partner with both technical expertise and digital capabilities.

Wastebits Provides the Solution

Integrated Waste Management Strategy

Wastebits delivered a tailored solution designed to reduce risk, improve sustainability, and drive operational efficiency. This included diverting 500,000+ pounds of blast media waste annually by connecting the facility with a specialized recycling partner. The team also implemented preventative industrial cleaning routines, significantly reducing downtime on production-critical systems such as the paint line—saving the company an estimated $250,000 per year.

Compliance and Environmental Risk Mitigation

To address compliance vulnerabilities, Wastebits helped reorganize the facility’s waste accumulation areas using 5S methodology—improving labeling, signage, and stream separation in accordance with RCRA guidelines. Additionally, Wastebits supported bulk shipments of up to 25,000 gallons of wastewater per day to ensure the facility remained in compliance with local POTW discharge standards, helping prevent environmental violations and reputational risk.

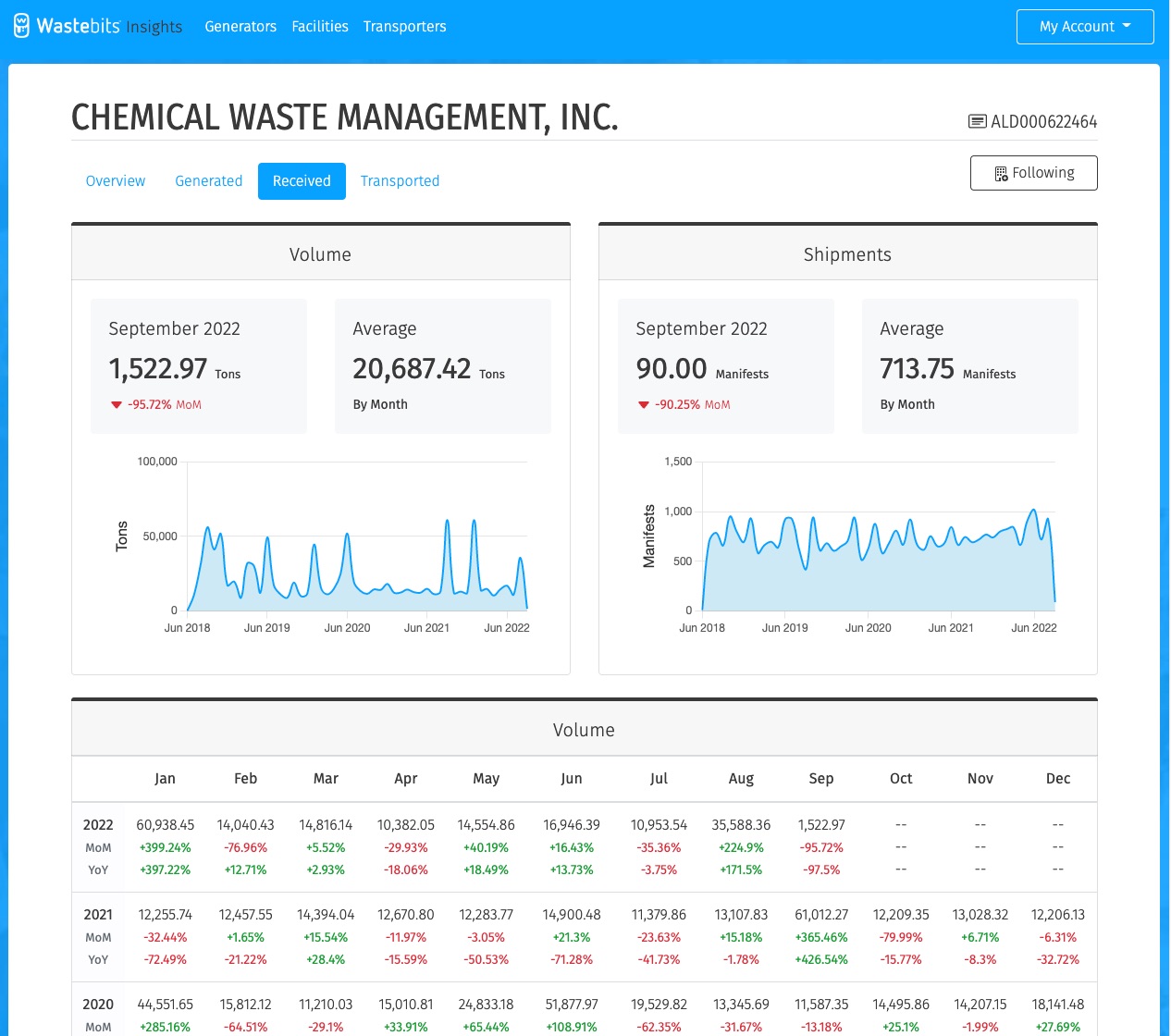

Technology That Simplifies and Scales

A key differentiator in the partnership was Wastebits’ digital platform. The software centralized waste tracking across all streams, streamlined manifest and documentation workflows, and enabled faster audits and reporting. By integrating technology with service, the facility gained full visibility and control over its waste operations—reducing administrative burden while maintaining regulatory confidence.

A Proven Impact

Since partnering with Wastebits, the manufacturer has realized more than $700,000 in total value—through avoided fines, reduced downtime, and improved sustainability. The results include over 500,000 pounds of waste diverted from landfills, more than $350,000 in compliance risk avoided, and $250,000 in annual savings through improved maintenance scheduling. This case exemplifies the power of combining operational expertise with software innovation to drive long-term environmental and financial success.

500,000

Pounds of waste diverted from landfills annually

$250,000

Saved annually in reduced downtime through preventative industrial cleaning

$350,000

In potential RCRA fines avoided through improved compliance practices

More Case Studies

👋 Let's Chat

Schedule a demo today to see for yourself how Wastebits can help run your business smoothly and increase profits.

P.S. Have you met David? He's a nice human, like you! Click the button above to see his calendar and click your preferred time (plus you'll see a picture of his sweet beard).

He'll ask a few questions and show you exactly what applies to your situation. There's no pressure, you'll make a more informed decision, and takes only 15-minutes. 🙌